Drywise filament dryer - effective printing with technical materials

:fill(white)/d2552a7b1bfafb6ead747e1655d182d0)

Are your prints with industrial filaments less than perfect? Wondering how to salvage old technical material that has been stored in a humid environment for an extended period? In this article, we discuss the issues caused by moist filament and explore the solutions available on the market.

3D printing in FFF (Fused Filament Fabrication) technology has undergone a dramatic transformation over the past four years: devices have become faster, cheaper, and most importantly, easier to use. Filaments have not lagged behind either. Basic materials like PLA, PET-G, or ABS are no longer the focus of interest. Today, filaments need to be multicolored, flame-retardant, or boast increased durability (preferably all at once). Attracted by promises of enhanced material properties, less experienced users often encounter significant challenges. More advanced filaments are harder to print, requiring enclosed chambers, preferably heated ones, and the material itself often needs to be dried before use.

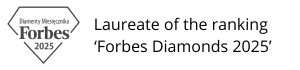

Although 3D printing technology has advanced significantly, we must not forget the fundamental rule: proper care of the filament is essential. Improperly stored material can lead to issues during and after printing. Printed models may fail to meet visual and durability requirements, primarily due to moisture absorbed by the material. Sometimes even freshly unpacked material from a sealed package can be too moist for printing. Filaments, by their nature, readily absorb moisture from the air, particularly materials like nylon or blends with carbon or glass fibers. What are the consequences? When printing with wet material, a popping sound can be heard from the nozzle. This indicates that water droplets in the filament are evaporating due to increased temperature and pressure, creating holes in the print. This results in unattractive prints and reduced durability. Moist filament also increases stringing (the appearance of fine hairs on the print), and in extreme cases, it can lead to nozzle clogging.

POPULAR SOLUTIONS

To address these challenges, various methods of drying filaments have been developed. The simplest and cheapest method involves drying the filament using the printer’s heated bed and chamber. However, the downside is that the printer is occupied during the drying process, and the filament is not dried evenly.

Drying filaments in an oven is another popular method. However, this is not an ideal solution either. Filaments often dry unevenly, and the oven temperature fluctuates, making it difficult to achieve precise settings. This carries a significant risk of overheating and damaging the material or the spool.

Many users turn to food dehydrators for drying filaments. This method requires modifications to the device to accommodate the spools. A major drawback of this method is that such dehydrators typically have a maximum temperature of 70°C and low efficiency. This means they are only effective for drying PLA and PET-G. Attempting to dry more technical filaments is possible but requires more time and offers no guarantee of success.

The most popular filament drying method is purchasing dedicated devices designed specifically for this purpose. These devices hold the spools and feed the filament directly into the 3D printer. Some devices can accommodate one or multiple spools and function like food dehydrators or use alternative drying mechanisms. An added advantage is the ability to load the filament directly from the dryer into the printer. More advanced devices of this kind come with preset drying settings tailored to specific types of filaments. While this may seem like the perfect solution, this method, like the previous three, shares two common disadvantages.

Filament dryer EIBOS EASDRY available in our store.

First, drying technical materials takes many hours – ranging from four to several dozen. Second, the efficiency of this process for demanding materials is relatively low. A dried filament can be stored in a sealed container and taken out only when needed for printing, but this solution takes up space, and the filament often requires re-drying after being removed from the container.

All these challenges are resolved by the Drywise dryer from Thought3D. The company, previously known for its Magigoo adhesive, has now introduced a solution aimed at industrial 3D printers with its innovative in-line drying method (drying the filament strand itself).

HOW DOES IT WORK?

The device is simple to use, with an intuitive interface combining a screen and LED indicators to guide the user through the process. To begin, select the filament type, its manufacturer, and the exact material variant. Thought3D collaborates with filament manufacturers to develop material profiles, so operators do not need to input the parameters manually. The device already includes profiles for ROSA3D FILAMENT materials such as ABS V0 FR, PA12 + CF15, and PC-PBT, with additional profiles planned for future updates.

Filament dryer Drywise.

Filament spools can be mounted in various ways: on a holder attached to the dryer, directly on the printer, or any other setup that suits the user’s workspace. This flexibility allows for efficient equipment arrangement and the use of larger spools. The key requirement is that the filament has unrestricted access to the dryer.

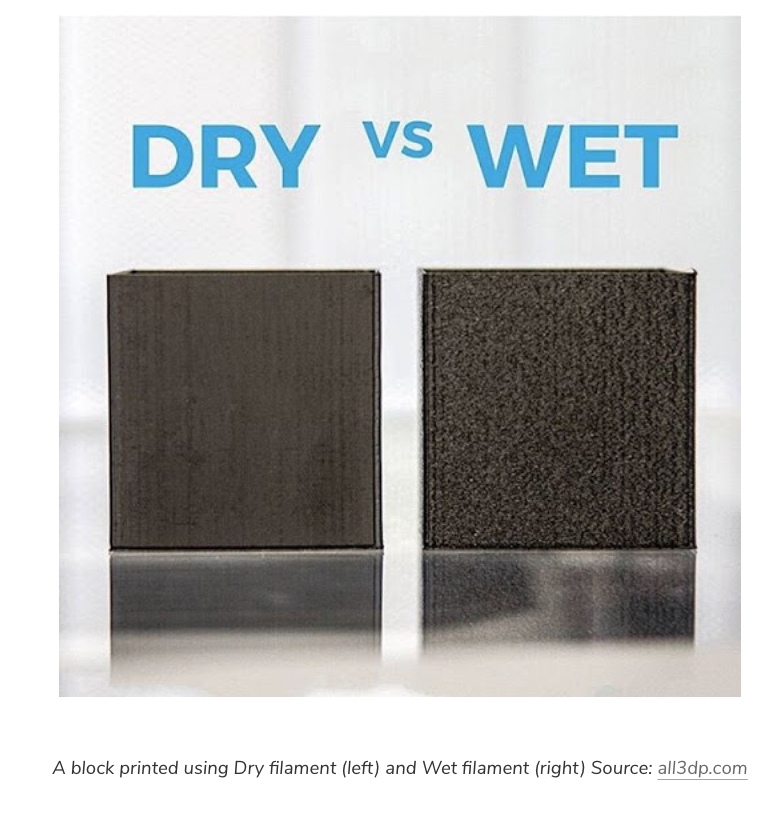

The Drywise dryer operates on a straightforward principle. The filament strand is fed into the device, where it is dried using hot air. Moisture extracted from the filament is absorbed by a desiccant in a dedicated container, ensuring the air is dried before recirculation.

The initial drying phase takes between 30 minutes to an hour, depending on the material type and the pre-configured settings developed by the device manufacturer for specific filaments. If the filament has been pre-dried, the initial drying step can be skipped at the user’s discretion.

After the filament is fed into the printer, an additional 15 minutes is needed to dry more of the filament strand. Once this is complete, printing can begin, and the dryer will continuously dry the filament during operation.

The dryer provides alerts for when the desiccant or O-rings need replacement to maintain the device’s airtight integrity. Spare O-rings and two desiccants are included in the package. Additionally, the manufacturer offers a Pre-Heater attachment for filaments with glass or carbon fibers. These materials are brittle, and the Pre-Heater softens the filament to make it more flexible, reducing the risk of breakage during operation. Moreover, the Pre-Heater’s design adjusts the filament’s entry angle into the dryer, further minimizing the chance of breakage before heating.

Pre-Heater add-on.

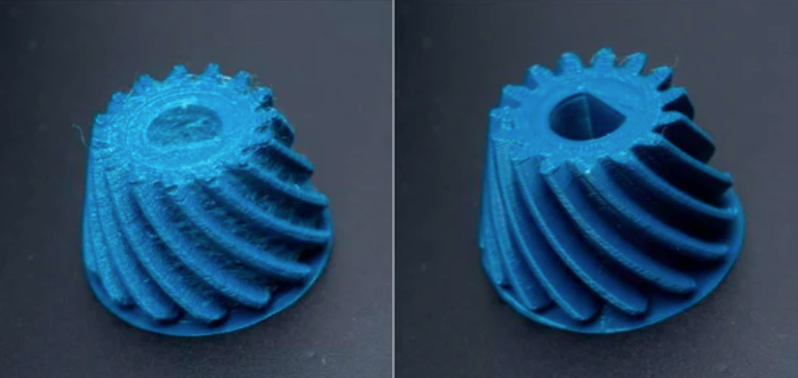

Thanks to the continuous drying process, Drywise ensures the highest quality and consistency of prints. Prints made with filament dried using the in-line method exhibit visually flawless results, free of defects like gaps in walls, rough surfaces, stringing, or burn marks, while also boasting superior strength.

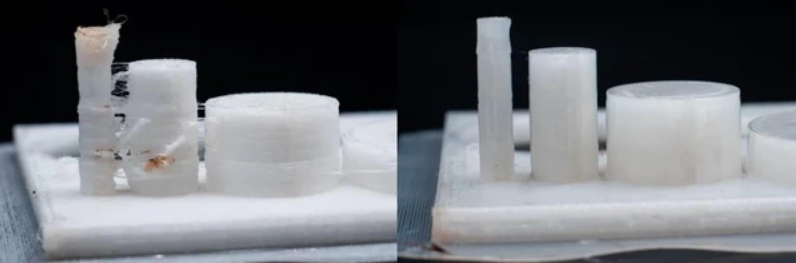

3D prints from wet (left) and dried by DryWise (right) filament.

The dryer is equipped with numerous sensors to monitor and control the drying process comprehensively. If the filament stops moving, Drywise can automatically pause the process, enhancing safety and user convenience.

SIGNIFICANT SAVINGS

Drywise users can eliminate one of the biggest challenges in industrial 3D printing: the long preparation time for materials before production. By eliminating the need for hours of filament drying in ovens, users can accelerate the production of items using more demanding materials. This translates to improved efficiency, the ability to complete more orders, and lower electricity costs.

Anyone running a 3D printing operation knows that, despite best efforts, partially used spools of filament often sit on shelves for extended periods. These materials are frequently discarded because drying them in an oven without guaranteed results isn’t cost-effective. The Drywise dryer, regardless of the filament’s condition or quantity, effectively dries the material, making it suitable for printing again.

A major issue in industrial 3D printing is the production of objects using large spools of filament. While these spools are more cost-effective than smaller ones, drying them in an oven poses a serious challenge. There’s no guarantee that the filament inside the spool will be properly dried. Often, only the outer layers of the material are dried, leaving the inner layers still wet. Drywise solves this problem by drying the filament strand directly rather than the entire spool.

Both the Drywise dryer and the Pre-Heater are available in our store.

ROSA PLAST SP. z o.o.

ul. Hipolitowska 102B

05-074 Hipolitów, POLAND

Email

eshop@rosa3d.pl

Our team is at your disposal on working days during the hours:

od 7:00 do 15:00

Follow us