PLA LW AERO – the art of reducing print weight

:fill(white)/79c268710fe5b96f0360c668e2679b6e)

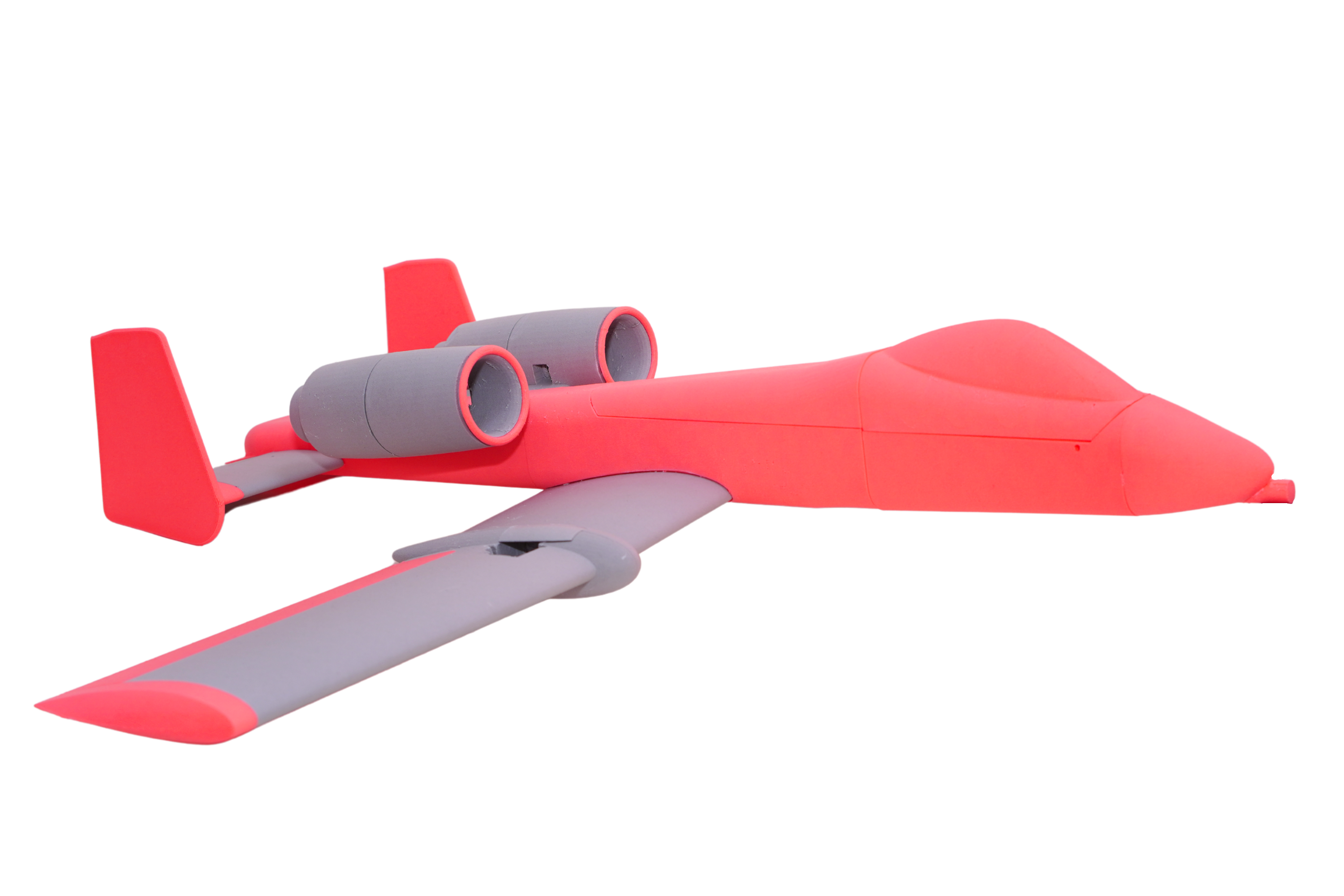

3D printers are amazing – not only do they save the day in everyday emergencies, but they also help you pursue your passions. A custom drone part? A piece of cosplay armor? Or maybe a lightweight airplane model? For all creators at heart, we’ve got something special – ROSA3D PLA LW AERO.

This is a filament that can work wonders. Thanks to its special formula, prints can be up to 2.5 times lighter than those made with standard PLA—while maintaining the same dimensions. How is that possible? The material is foamed, which means it slightly “expands” during printing, creating a porous structure. The result? Not only ultra-lightweight prints, but also nearly invisible layers – the finished model looks more cast than 3D printed.

ROSA3D PLA LW AERO is the perfect choice for fans of remote-controlled flying models, where every gram counts. But it also works great for creating cosplay props, lightweight decorations, or other creative DIY projects.

Just set the flow rate (the amount of filament fed during printing) correctly and you’re good to go – let your ideas take off! You’ll find simple, step-by-step instructions on how to do this later on.

So if you want your projects to be light as a feather, look professional, and truly impress – reach for ROSA3D PLA LW AERO. It’s a filament that can really lift your ideas off the ground!

What can you use ROSA3D PLA LW AERO for?

PLA LW AERO Neon Orange i Gray.

This filament truly shines when lightweight and appearance are key! Its foamed structure makes the layers almost invisible, and the surface is perfect for painting, sanding, or other post-processing. It opens up a world of possibilities for hobbyists and makers!

It’s perfect for applications such as:

• RC airplanes and drones – every gram saved means longer flight time and better maneuverability,

• hand-launch models – lightweight and durable, ideal for fun and aerodynamic testing,

• electronics enclosures and RC builds – when weight truly matters,

• cosplay costumes – large, eye-catching armor pieces or accessories won’t weigh you down after a few minutes of wearing,

• props for films and photoshoots – fast printing, low weight, easy to paint – what more could you want?

And that’s just the beginning! If you’ve got an idea for something big, light, and unique – this material won’t let you down.

Description and calibration

ROSA3D PLA LW AERO is primarily composed of polylactide (known for its user-friendly printing) and a foaming agent. The foaming effect is controlled by adjusting the temperature, and in our material, it begins at around 220 °C. This expansion not only reduces the overall weight of the print but also gives it a slightly rough, textured surface that effectively hides layer lines. Additionally, the foamed filament is easier to post-process — prints can be easily cut and sanded.

Color comparison of PLA LW AERO: Black, Gray, White, Yellow, and Neon Orange.

| Printing parameters | ||||

| Nozzle temperature [°C] | 220 – 250 | |||

|---|---|---|---|---|

| Bed temperature [°C] | 40 – 60 | |||

| Printing speed [mm/s] | 5 – 60 | |||

| Cooling fan speed [%] | 0 – 20 | |||

| Enclosed chamber | no | |||

| Nozzle type | brass/steel | |||

Foaming efficiency will vary depending on the printer, primarily due to hotend design. Based on our tests on various printers, ROSA3D PLA LW AERO achieves the strongest foaming effect at temperatures between 240°C and 250°C. For these temperatures, the extrusion multiplier should be set around 0.4.

Wall thickness variation in PLA LW AERO depending on temperature.

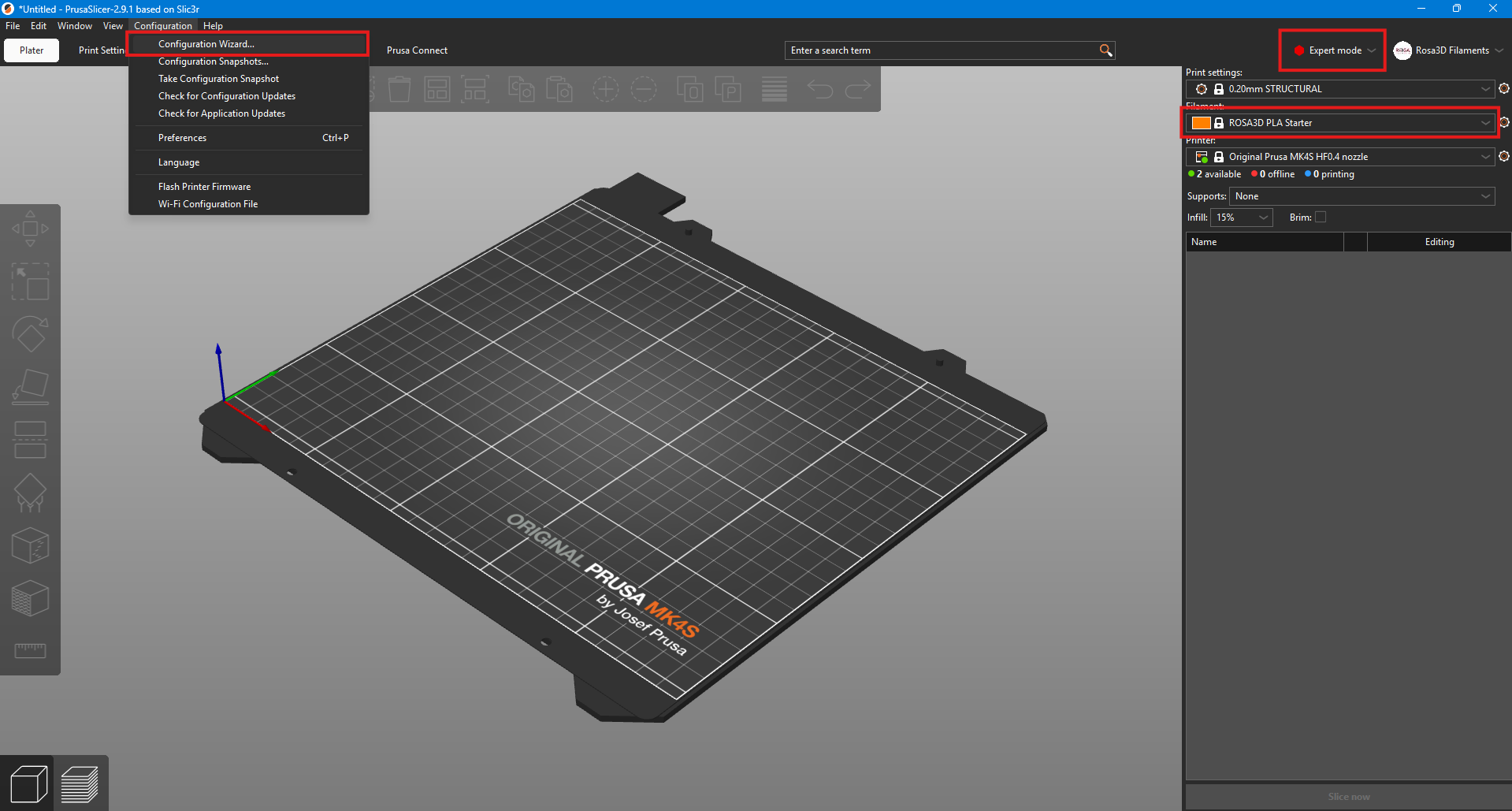

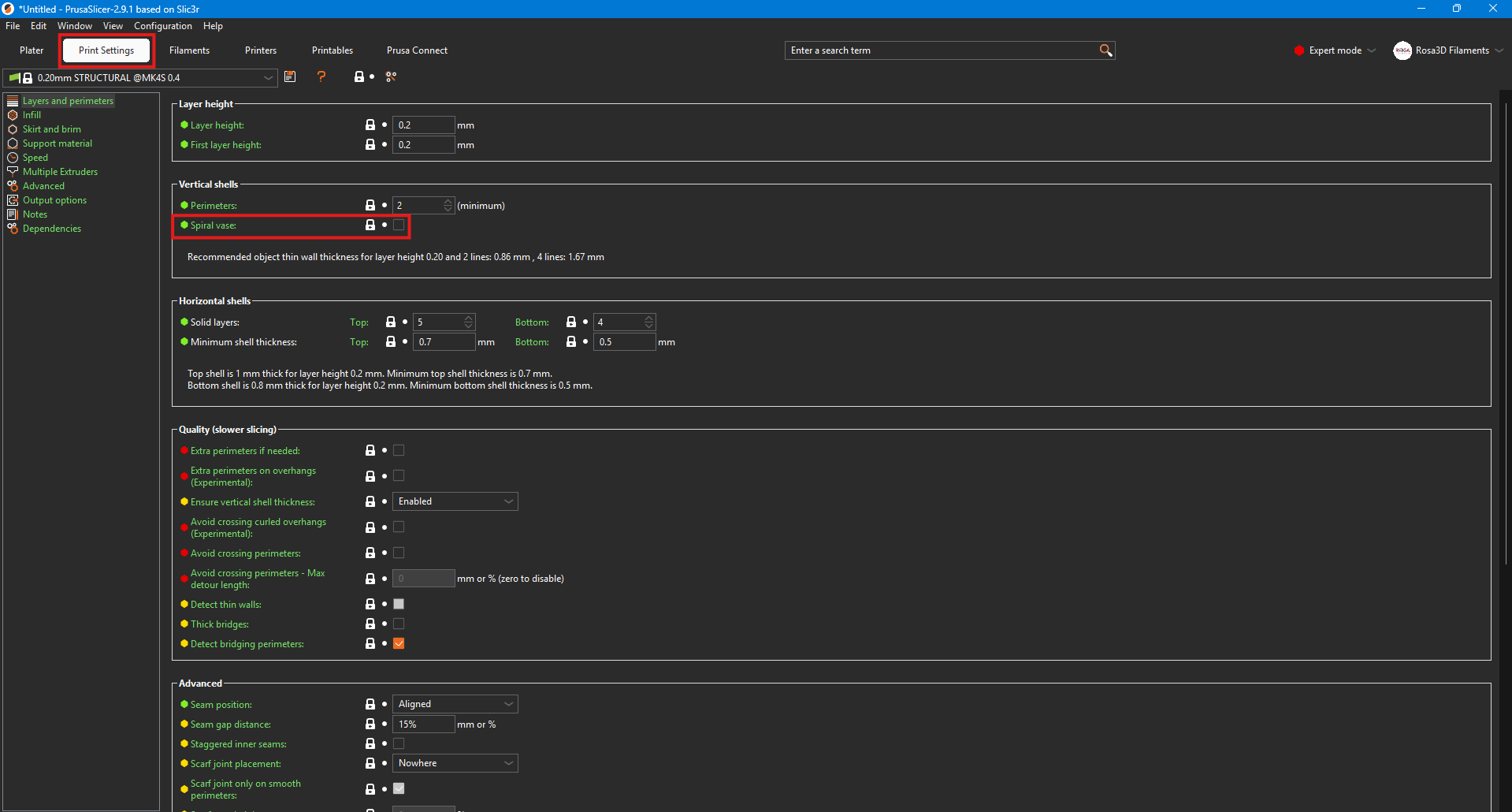

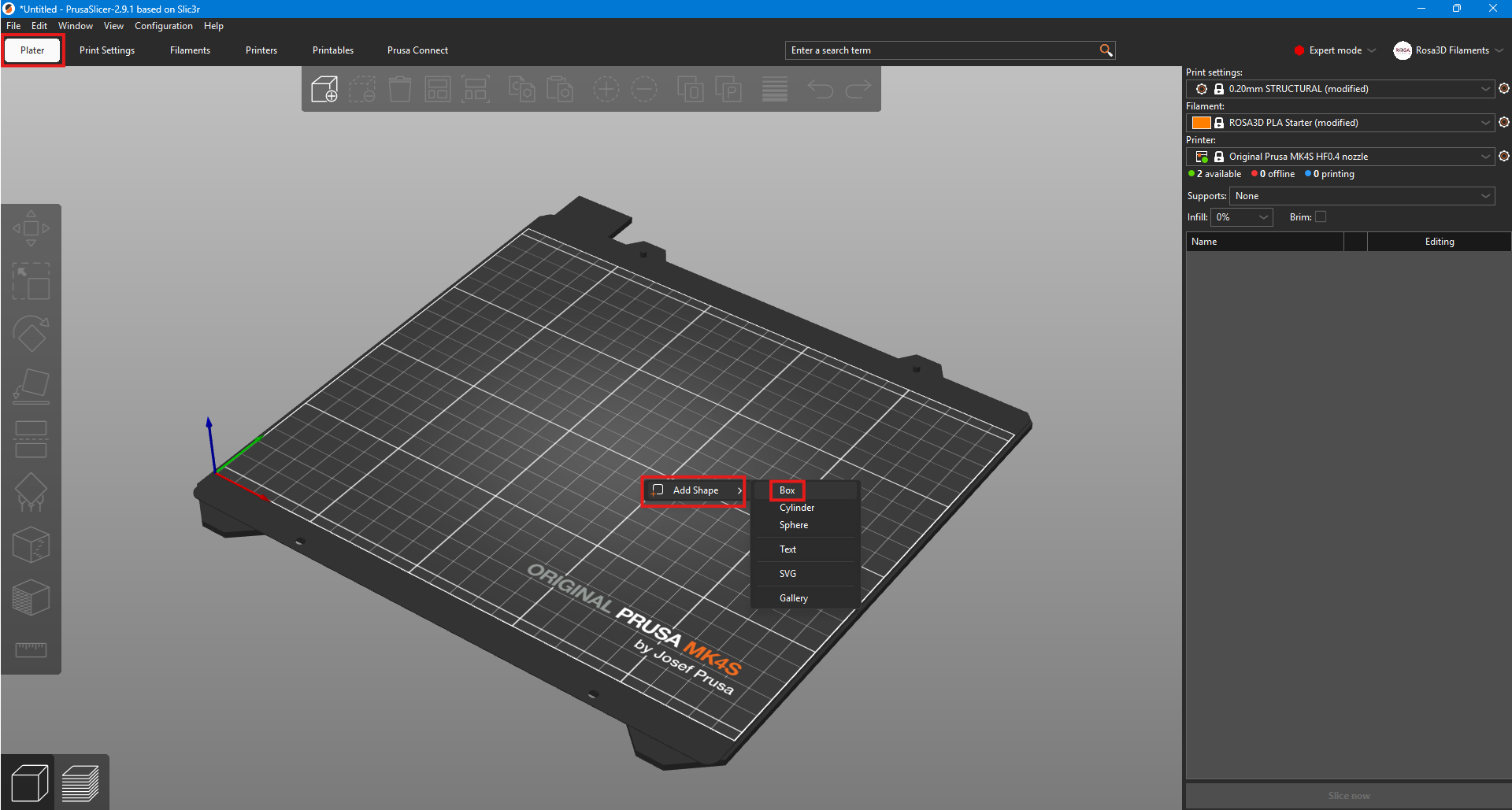

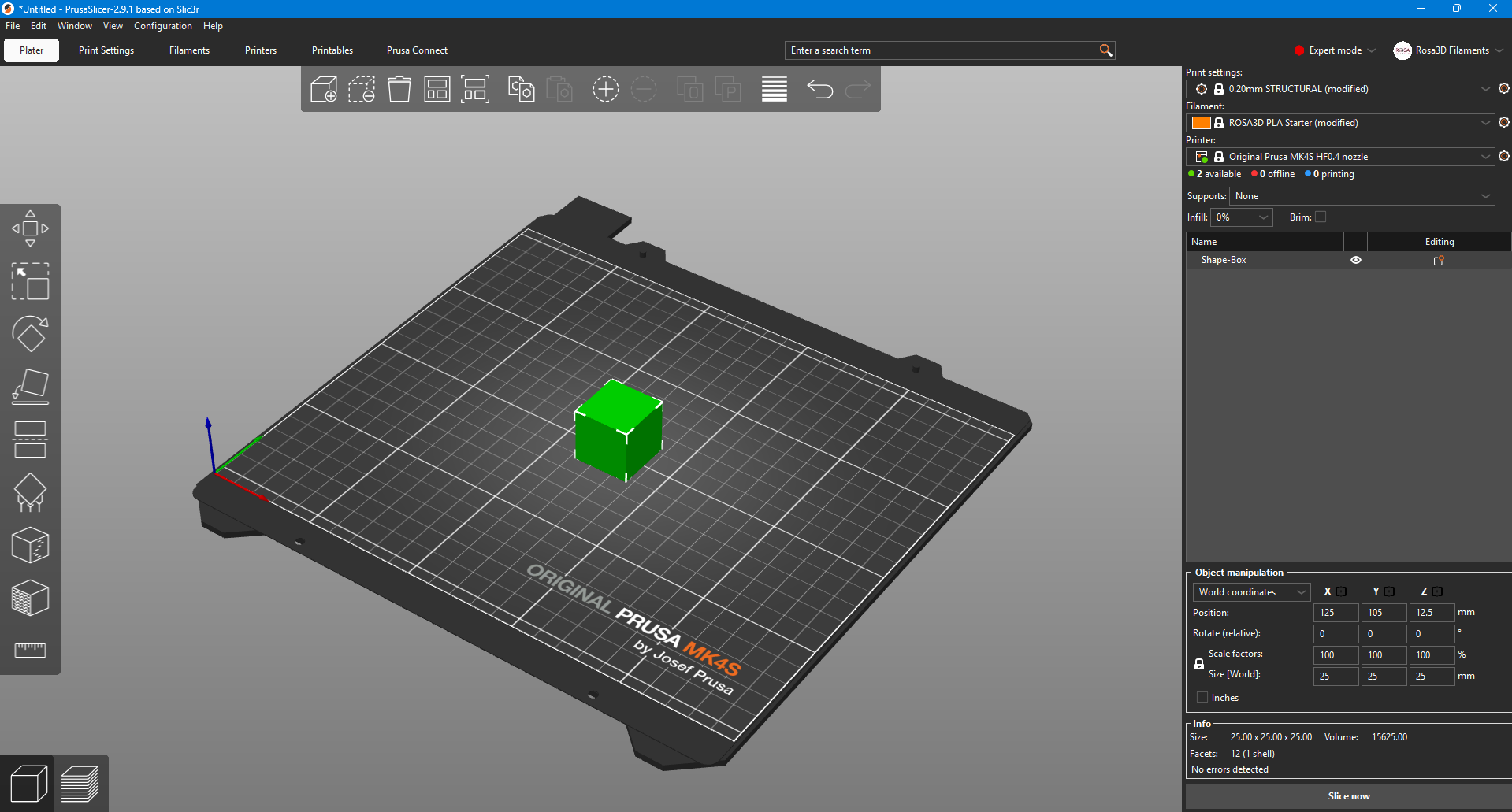

For best results, we recommend calibrating the flow rate yourself at different temperatures within the 220–250 °C range. A caliper will be an essential tool for this process. In PrusaSlicer, adjust the settings as shown in the screenshots below.

From the filament list, select the ROSA3D PLA Starter profile. If it’s not available, add it using the Configuration wizard. Also, make sure to enable Expert mode.

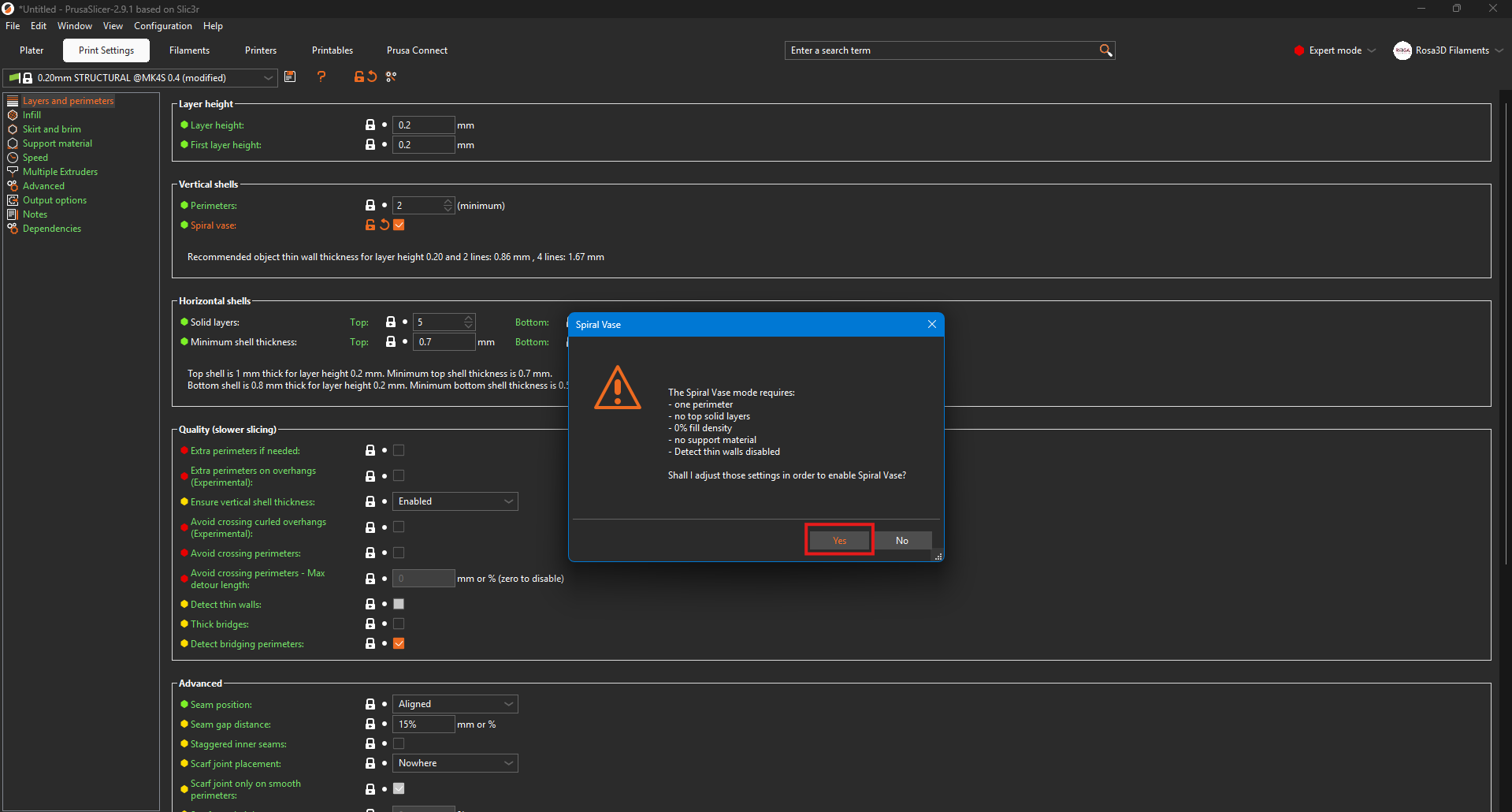

In the Print Settings tab, make sure to enable Spiral vase.

And confirm the changes.

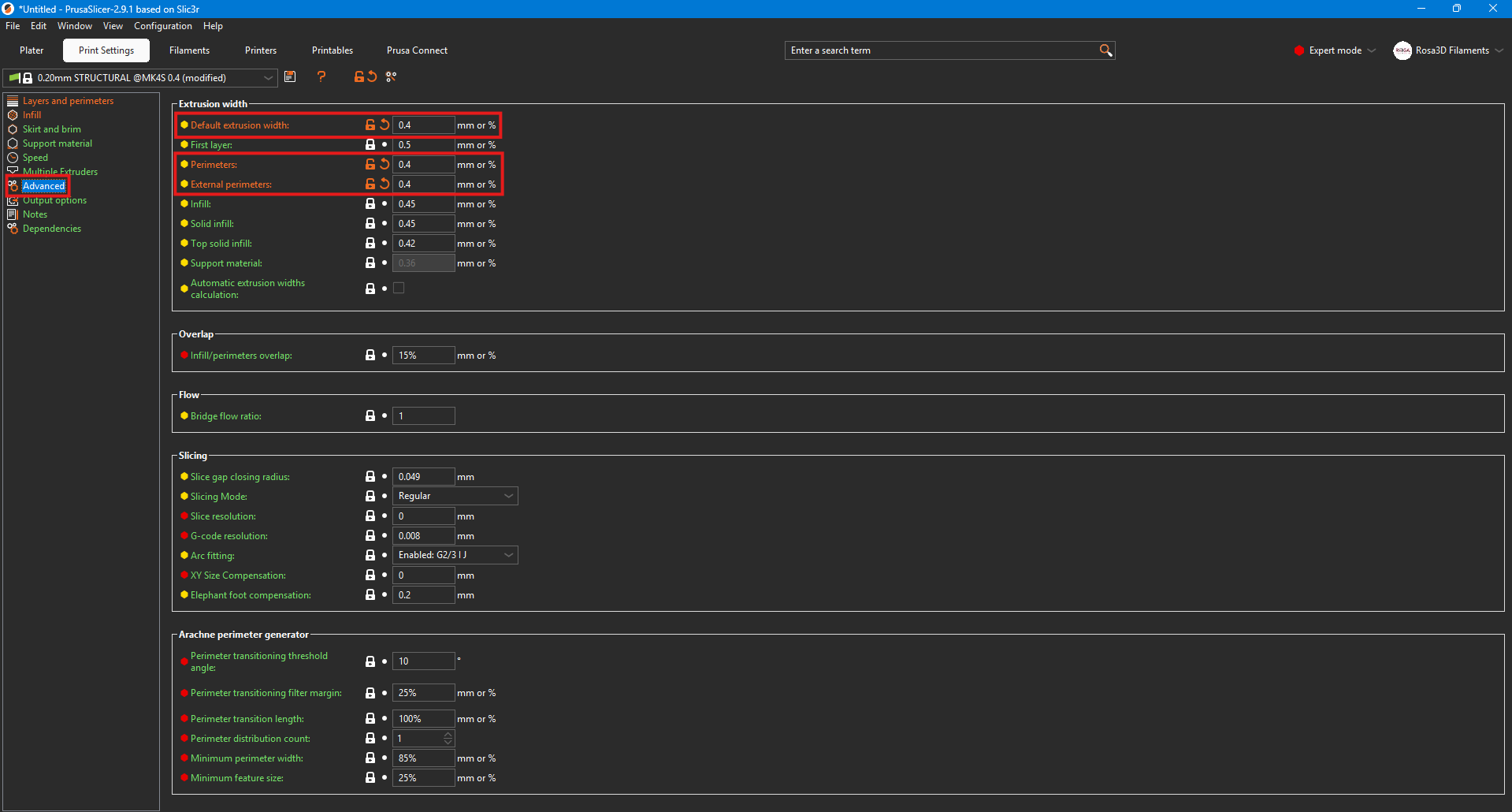

In the same tab, under the Advanced options, adjust the values according to the screenshot above.

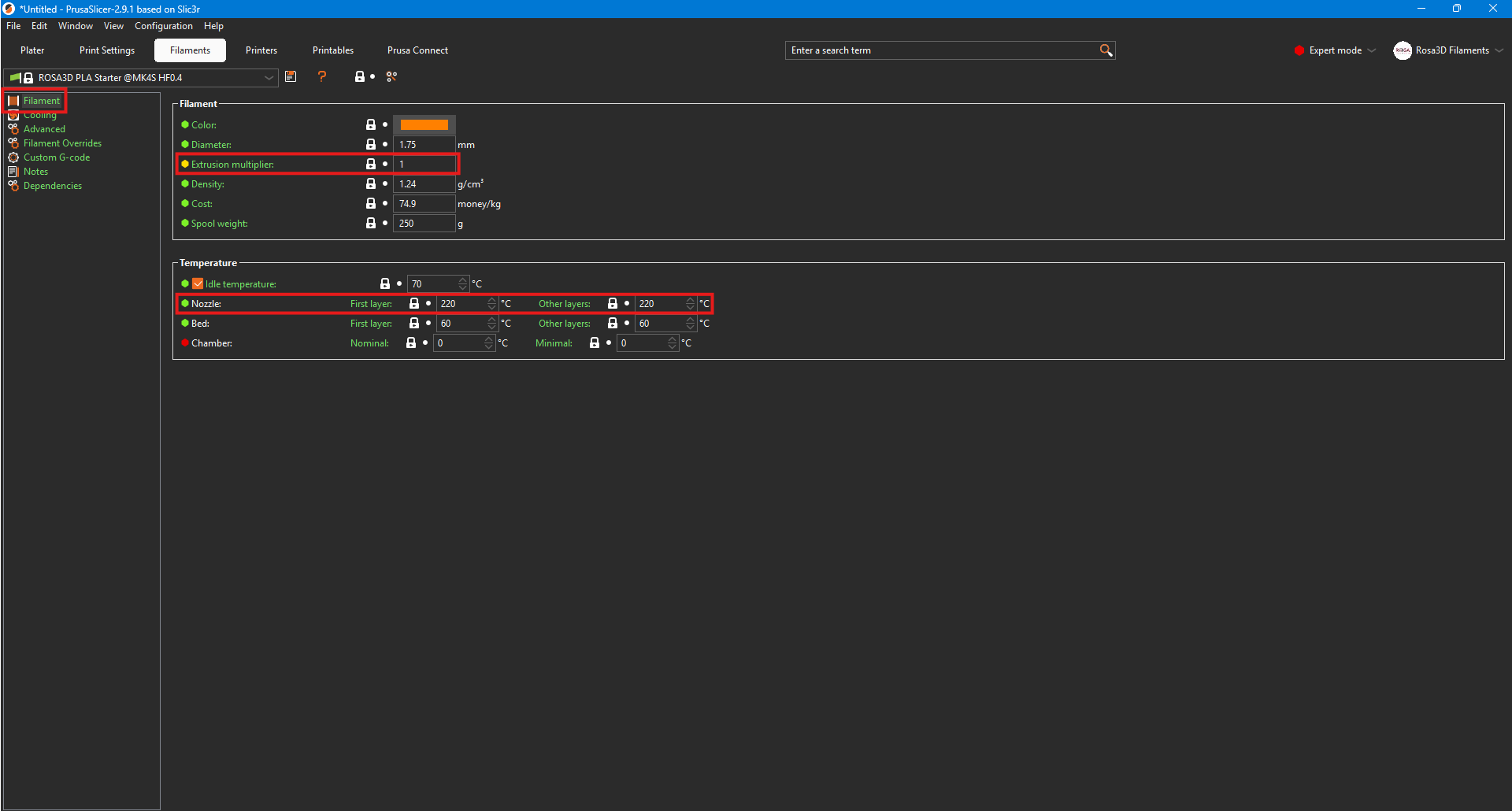

In the Filaments tab, pay attention to the values marked with rectangles. During calibration, the Extrusion multiplier should be set to 1. The temperature should be adjusted within the 220–250 °C range, depending on your needs.

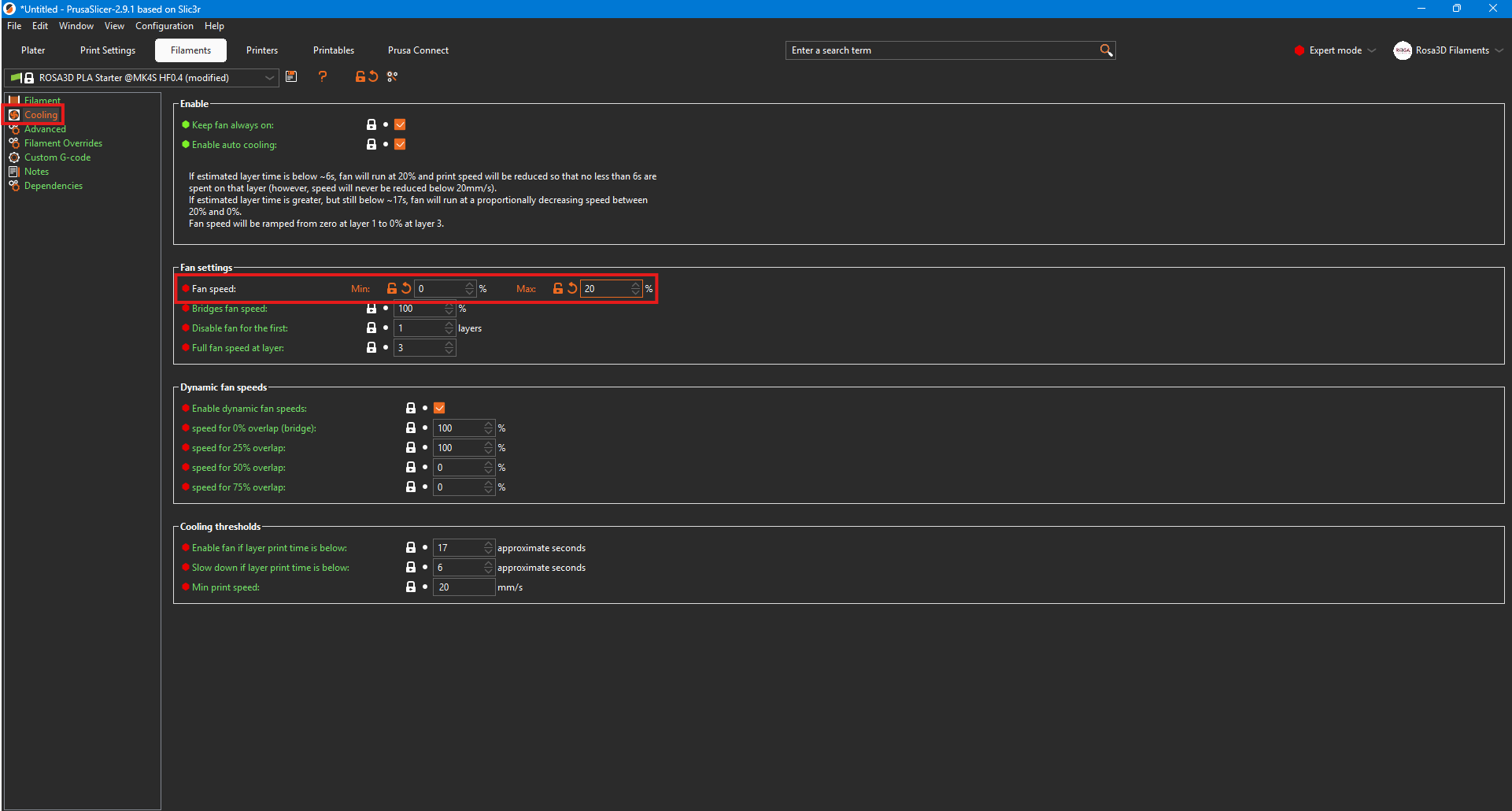

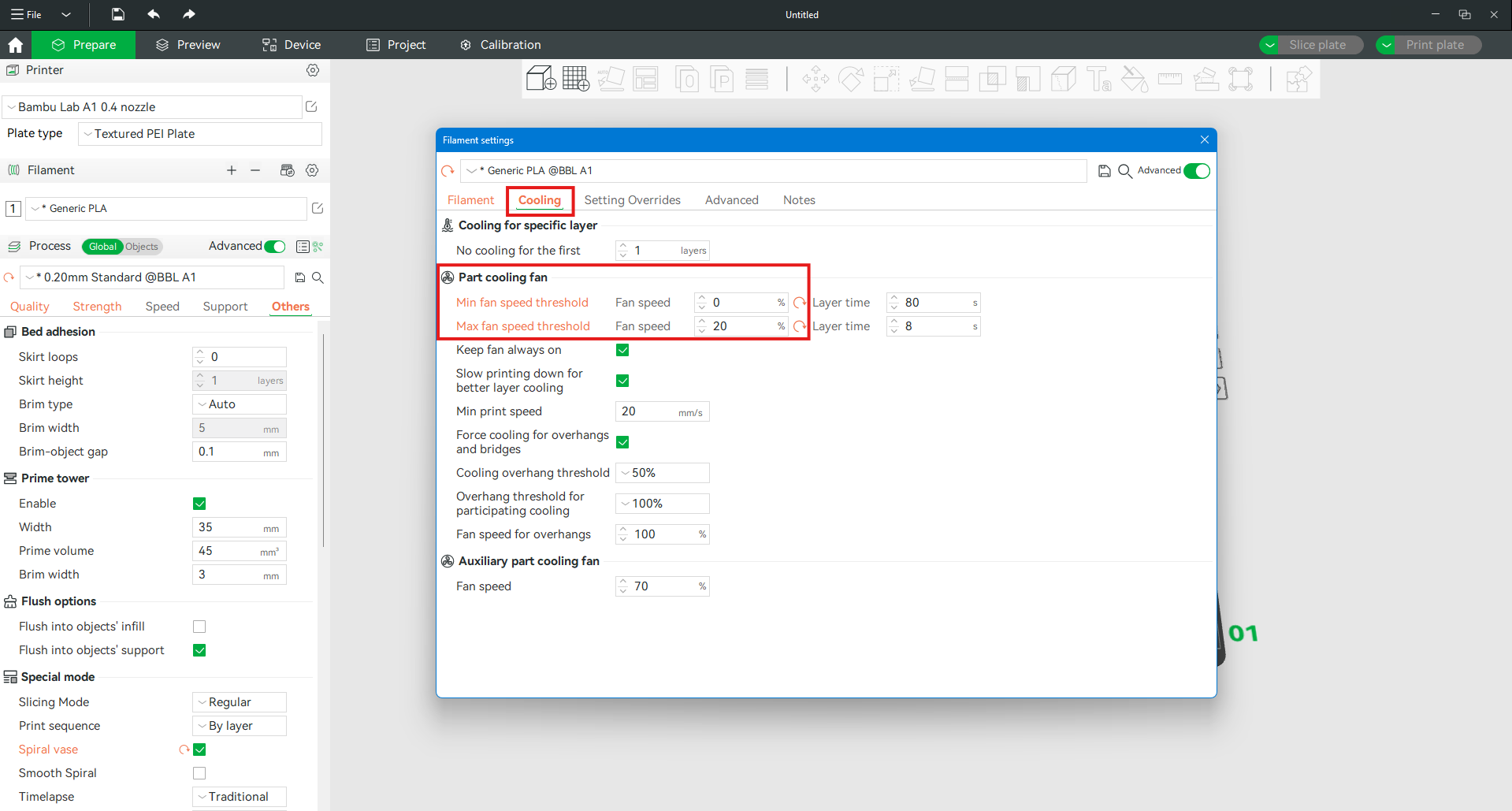

And adjust the fan speeds according to the screenshot above.

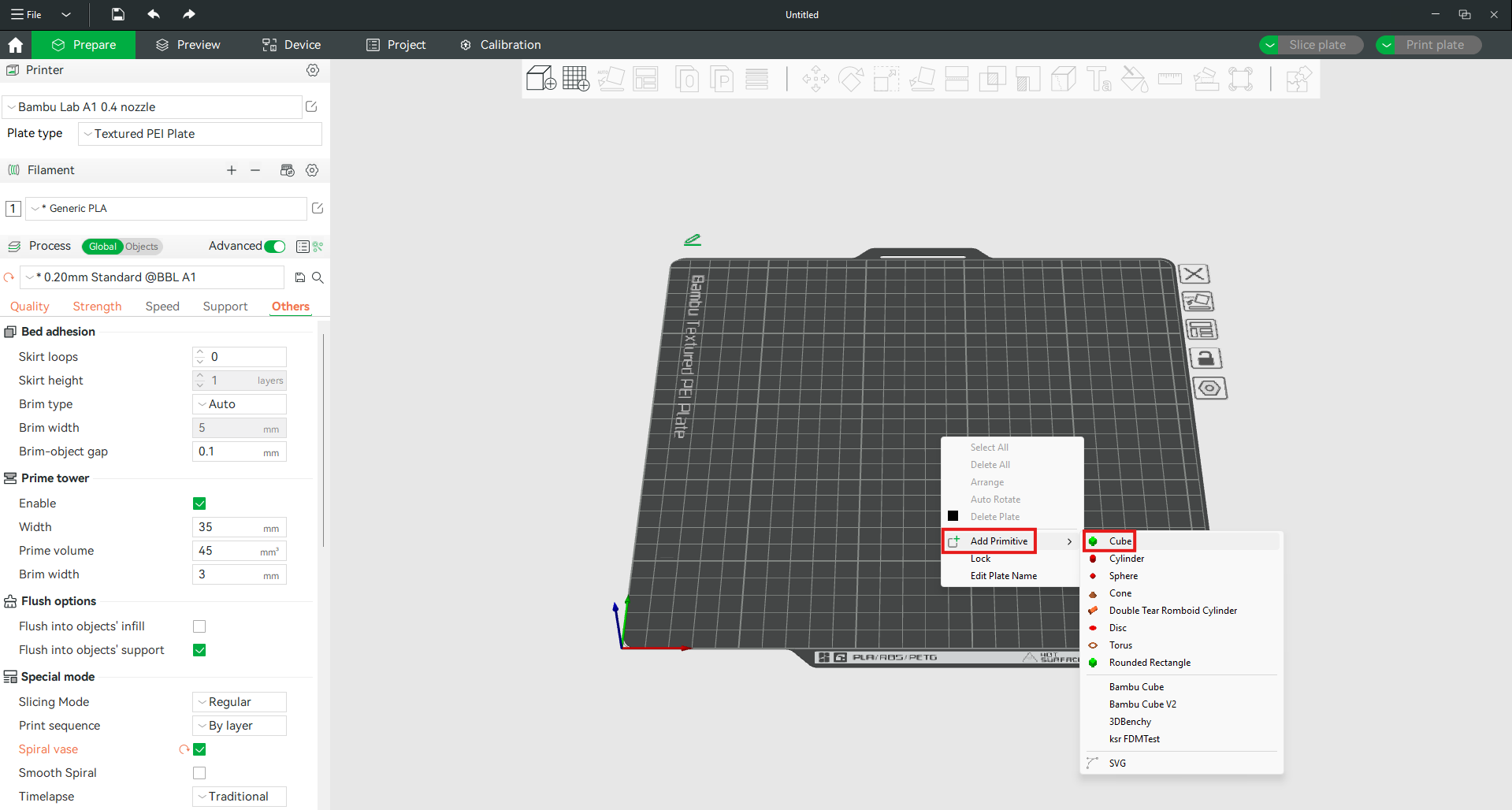

Next, go to the Plate tab, right-click on the empty area of the print bed, hover over

Once the file is prepared, it should be sliced and printed.

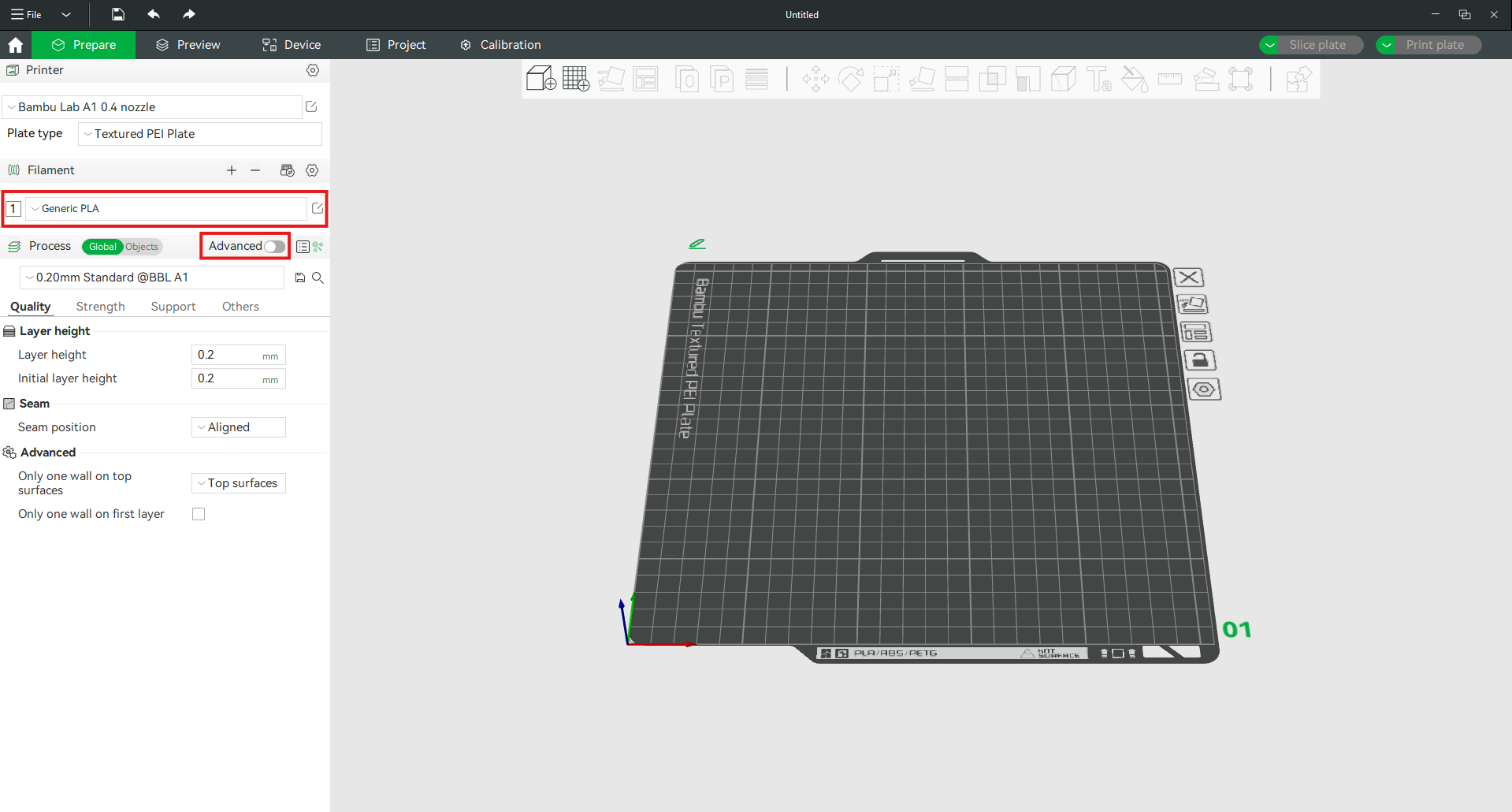

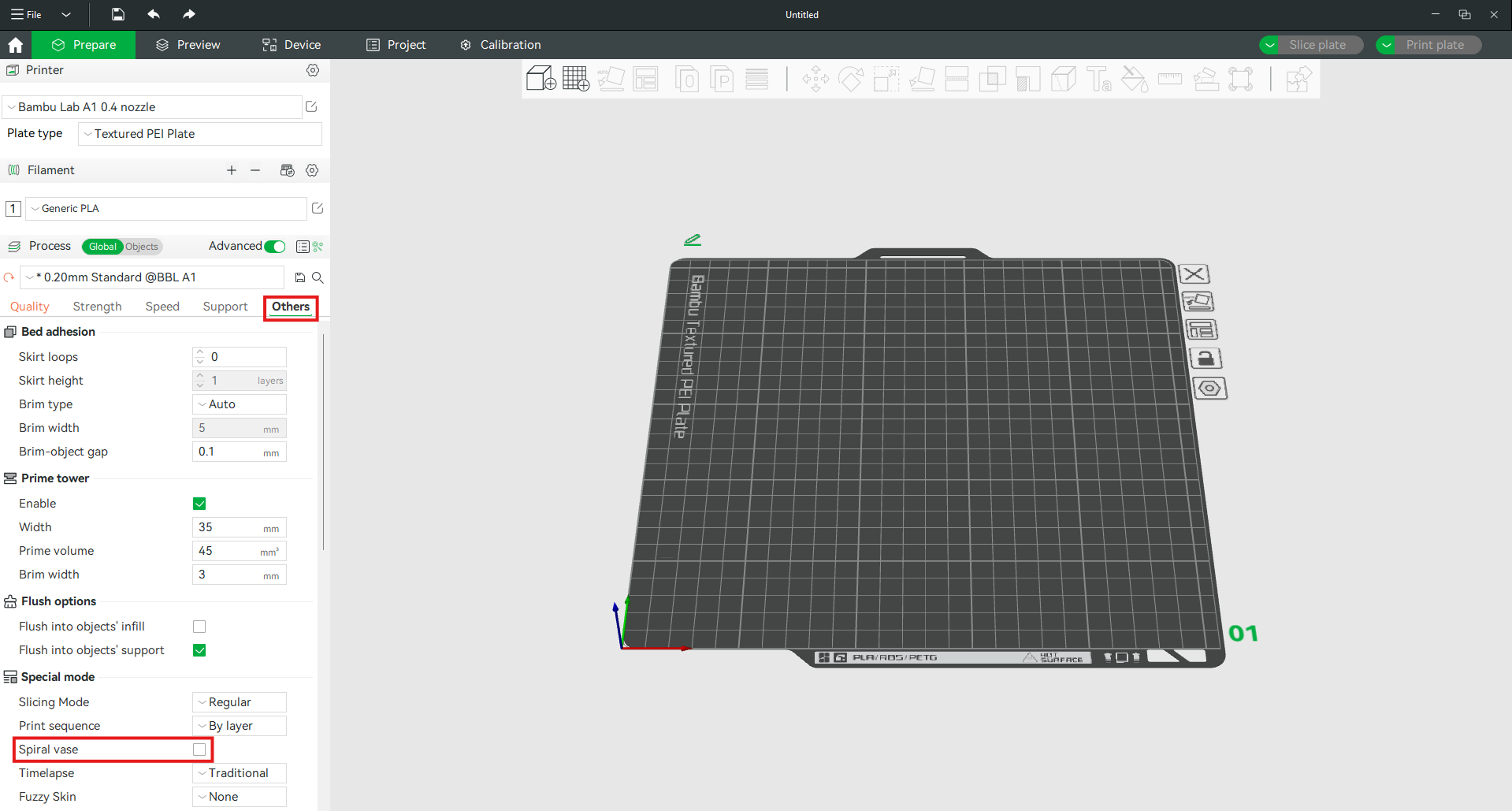

In BambuStudio, adjust the settings according to the screenshots provided below.

From the filament list, select the Generic PLA profile and enable Advanced options.

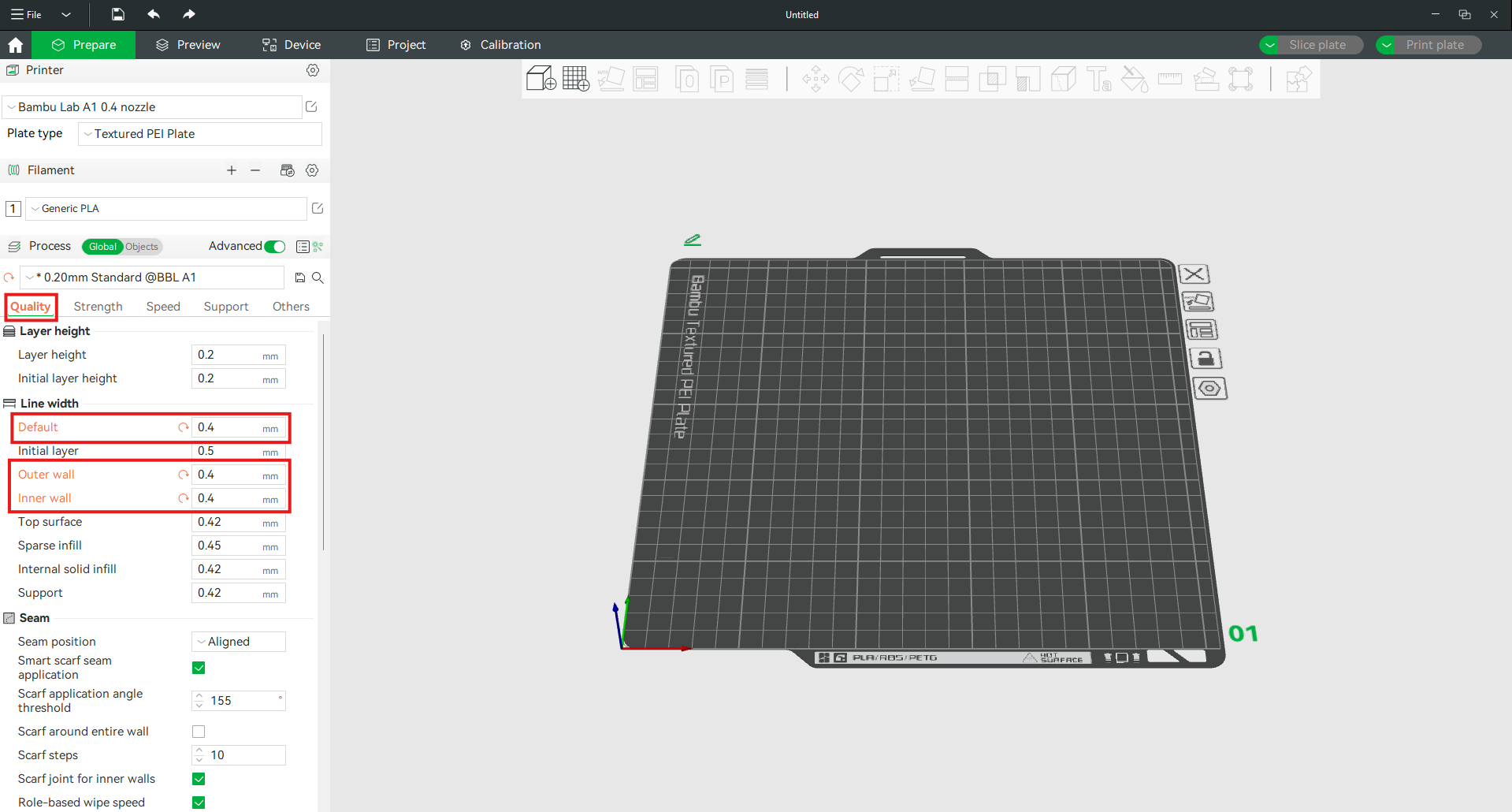

In the Quality tab, adjust the Line Width settings according to the screenshot above.

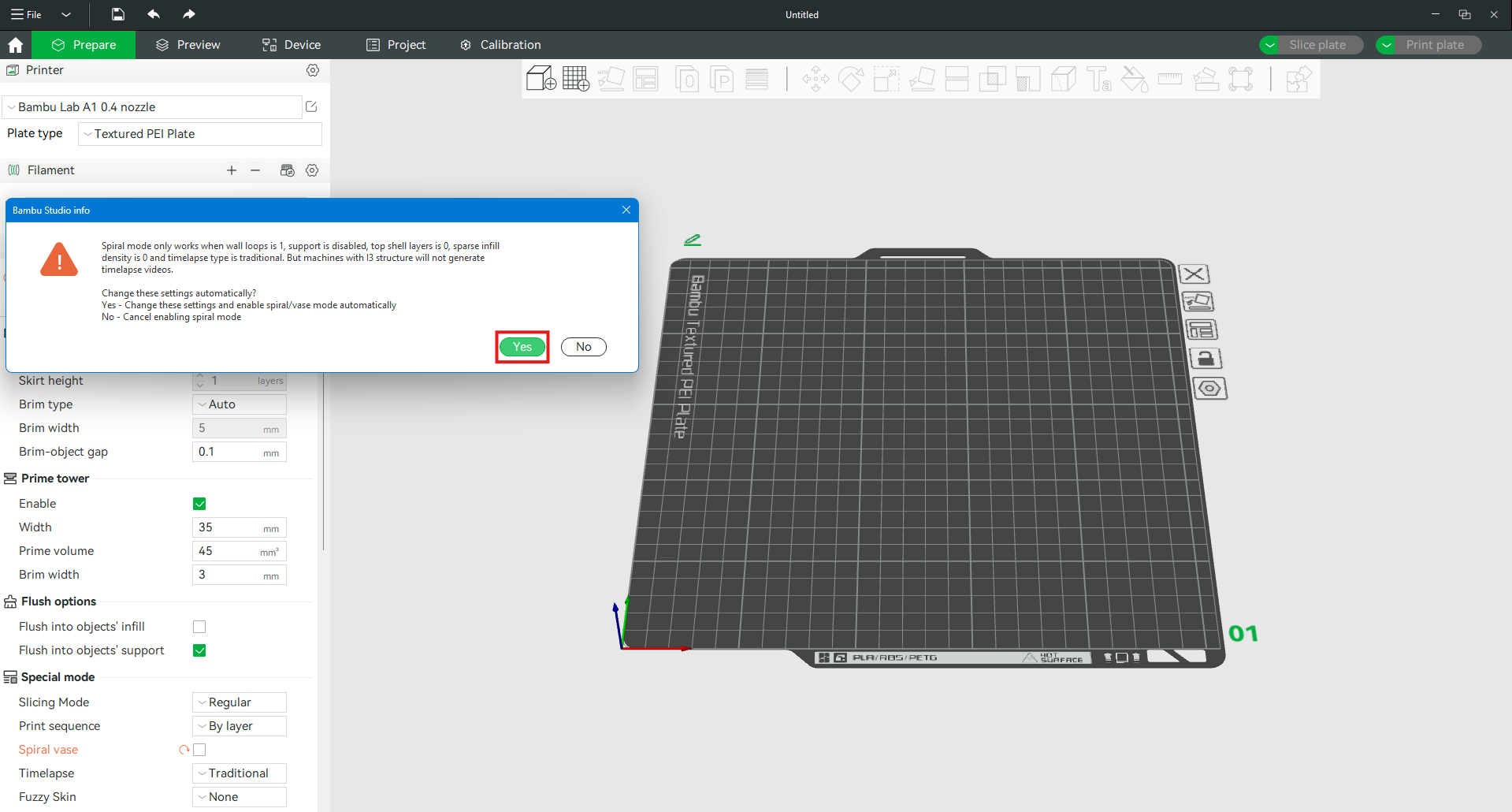

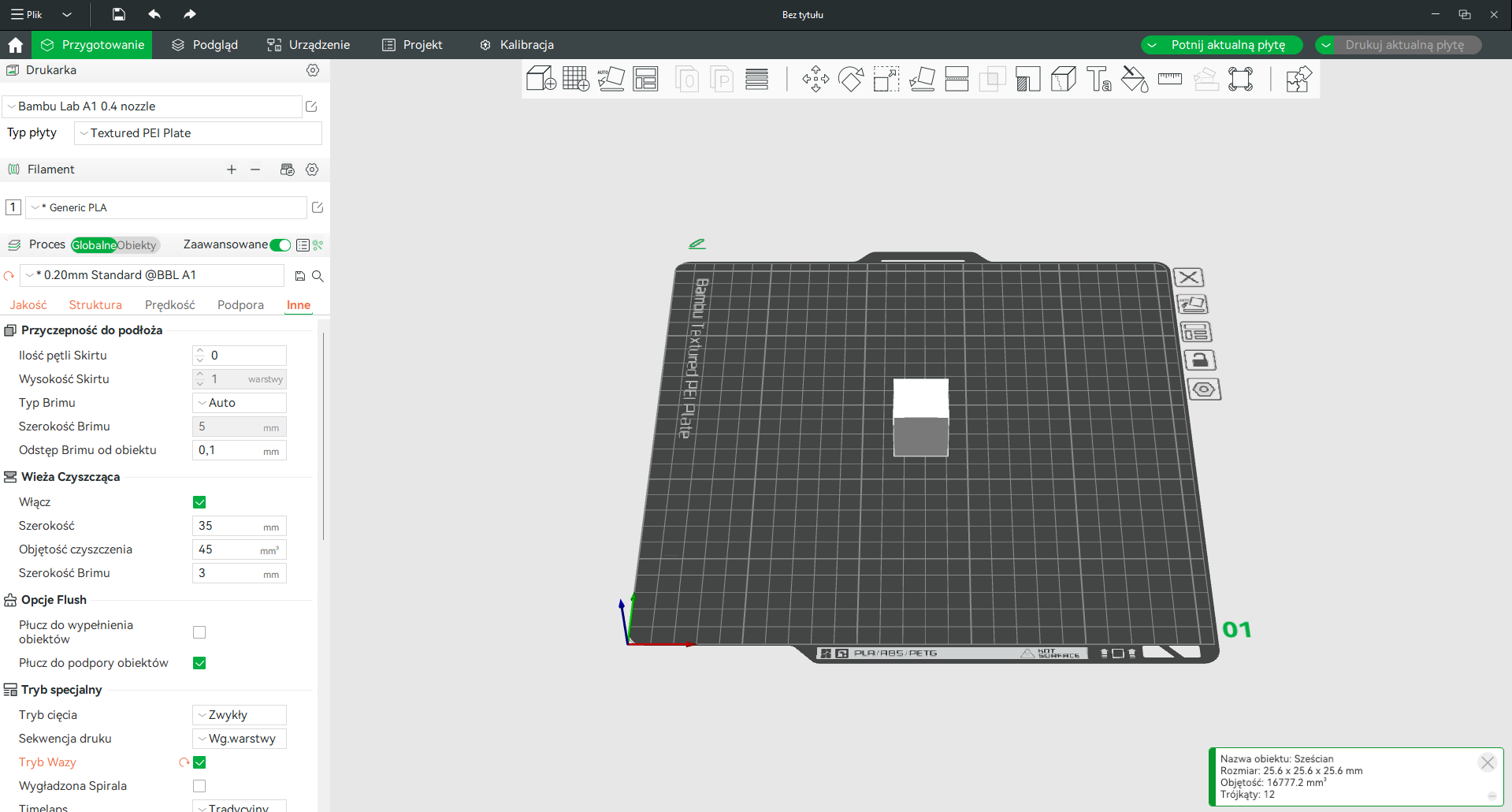

In the Others tab, enable Spiral vase.

And confirm the changes.

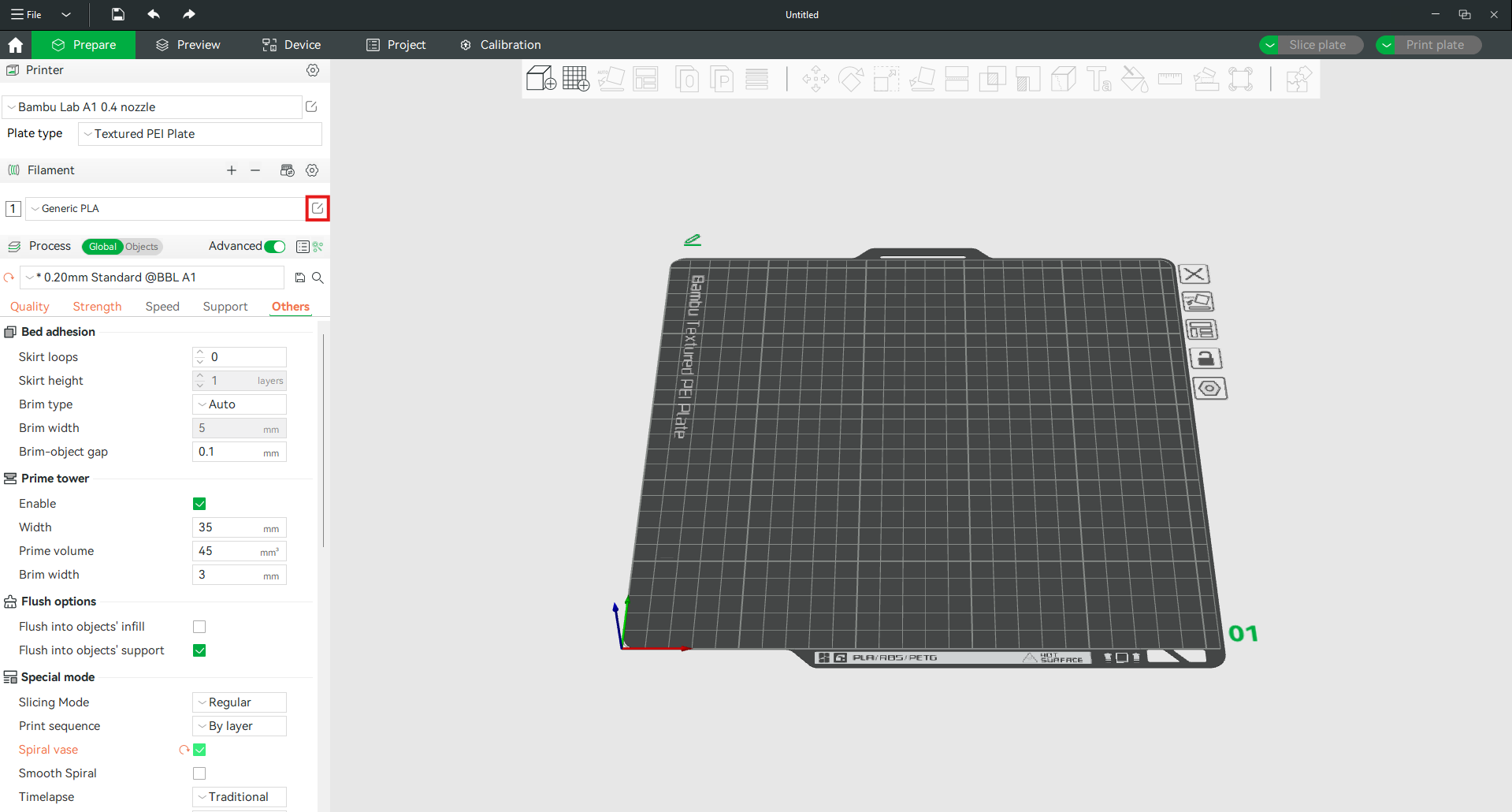

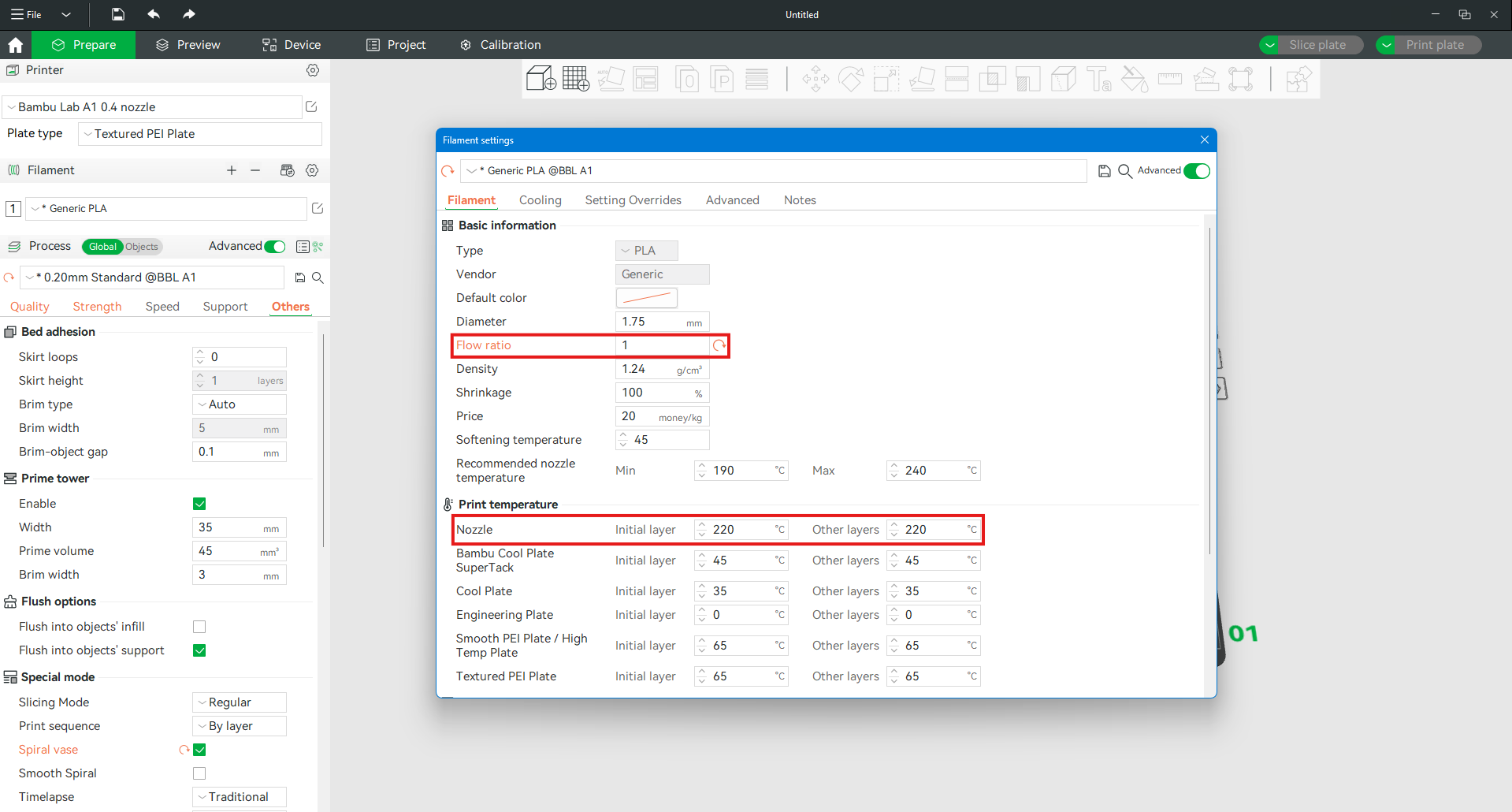

Next, you need to edit the filament settings.

Pay attention to the Flow ratio — during calibration, it should be set to 1. The printing temperature should be adjusted within the range of 220–250°C, depending on your needs.

In the Cooling tab, adjust the settings according to the screenshot above, then close the filament settings window.

Next, right-click on an empty area of the printer bed, hover over Add Primitive, and select Cube.

The prepared file should then be sliced and printed.

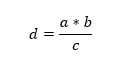

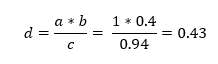

After printing, measure the wall thickness. To estimate the new extrusion multiplier, use the following simple formula:

where:

a – extrusion multiplier used during the print

b – wall thickness set in the slicer

c – measured wall thickness

d – new extrusion multiplier

As an example, the new extrusion multiplier will be calculated based on the values from the previous image.

| Data | ||||

| a – extrusion multiplier during printing | 1 | |||

|---|---|---|---|---|

| b – set wall thickness | 0.4 | |||

| c – measured wall thickness | 0.94 | |||

The new extrusion multiplier is 0.43. This is a theoretical value and should be verified during actual printing.

ROSA PLAST SP. z o.o.

ul. Hipolitowska 102B

05-074 Hipolitów, POLAND

Email

eshop@rosa3d.pl

Our team is at your disposal on working days during the hours:

od 7:00 do 15:00

Follow us